Before you purchase any replacement posts for your keg, you’ll need to determine the brand/maker of that keg. You can figure this out by finding the stamp or markings on the side of the keg.

- Cornelius, Ball Lock (all types) GAS 19/32″ – 18 LIQUID 19/32″ – 18 – View +

- Cornelius, Pin Lock (all types) GAS 19/32″ – 18 (2 Pin) LIQUID 19/32″ – 18 (3 Pin) – View +

- Cornelius Spartan 19/32″ – 18 19/32″ – 18 – Shop ++

- Cornelius R (Pin Lock) 19/32″ – 18 (2 Pin) 19/32″ – 18 (3 Pin) – Shop ++

- Firestone V, VI & Super Challanger, Ball Lock* GAS 9/16″ – 18 LIQUID 9/16″ – 18 – View +

- Firestone Challenger, ball lock (racetrack) GAS 11/16″-18 LIQUID 3/4″-18 – +

- Firestone, Pin Lock (all types) GAS 9/16″-18 (2 Pin) LIQUID 9/16″-18 (3 Pin) – View +

- Firestone A (Pin Lock) 9/16″ – 18 (2 Pin) 9/16″ – 18 (3 Pin) – Shop ++

- Firestone R (Pin Lock) 9/16″ – 18 (2 Pin) 9/16″ – 18 (3 Pin) – Shop ++

- Firestone Challenger 11/16″ – 18 3/4″ – 18 – Shop ++

- Firestone Super Challenger 9/16″ – 18 5/8″ – 18 – Shop ++

- Firestone V Challenger 9/16″ – 18 5/8″ – 18 – Shop ++

- Firestone VI Challenger 9/16″ – 18 5/8″ – 18 – Shop ++

- John Wood 85, Ball Lock (racetrack)* GAS 11/16″-18 LIQUID 3/4″-18 +

- John Wood RA or RC, Pin Lock GAS 19/16″-18 (2 Pin) LIQUID19/16″-18 (3 Pin) – +

- John Wood 85 11/16″ – 18 3/4″ – 18 – Shop ++

- John Wood RA (Pin Lock) 9/16″ – 18 (2 Pin) 9/16″ – 18 (3 Pin) – Shop ++

- John Wood RC (Pin Lock) 9/16″ – 18 (2 Pin) 9/16″ – 18 (3 Pin) – Shop ++

- AEB, Ball Lock GAS 19/32″-18 LIQUID 19/32″-18 – View +

- AEB Kegs 19/32″ – 18 19/32″ – 18 – Shop ++

- Super Champion 19/32″ – 18 19/32″ – 18 – Shop ++

* The vast majority (99%) of Firestone Ball Lock Kegs on the market use the same post except for the original Challenger, which had “racetrack” style lids. Racetrack style lids had straight sides like a race track and are rare. All other kegs had standard rounded sides.

+Thank you to Keg Connection for this information – Complete Lineup of Posts and Poppets at Keg Connection

++Thank you to Keg Outlet for this information – Complete Lineup of Posts and Poppets at Keg Connection

Related: What’s the Difference Between Pin Lock and Ball Lock Kegs?

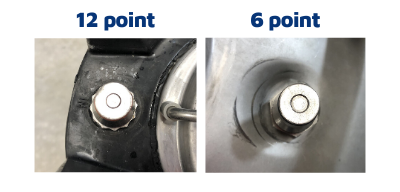

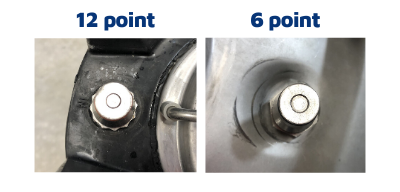

What about Wrench Sizes? Find Compatible Tools

+ Keg Connection Says… ⭐⭐⭐⭐⭐ The Reviews Are In – BEST KEGS EVER

18+ Liter Ball Lock Keg | Fully Remanufactured (AEB/SAFER/Cornelius) | SEE DESCRIPTION

More Info

From the product description, check product page for current description, price and availability:

18+ Liter Ball Lock Keg | Fully Remanufactured (AEB/SAFER/Cornelius)

These are top-tier, refurbished Corny kegs made of stainless steel. With stainless steel costs climbing and high-quality used kegs becoming increasingly scarce, this is an offer you won’t want to overlook.

Every keg in our collection undergoes a comprehensive refurbishment process. This includes deep cleaning, machine polishing, and the replacement of o-rings on the lid, PRV, as well as liquid and gas dip tubes, in addition to two o-rings on each post. These kegs are all sourced from elite brands, including AEB, SAFER, and CORNELIUS.

Additional Information on Our Refurbished Kegs:

Though these kegs are pre-owned, they may exhibit minor cosmetic imperfections such as small dings and scratches that couldn’t be completely polished away. None of these issues impact their functionality.

After the cleaning and polishing operations, some residue might be present on either the keg’s exterior or its rubber components. While it may transfer onto your hands, this is merely a reminder that all kegs—whether new or used—need to be meticulously cleaned before usage. Proper sanitization is also crucial before filling them with any beverage.

A subset of these kegs has experienced sun damage to the rubber areas, affecting the seal. This could lead to the formation of black marks, particularly when the rubber is wet, although this is less likely when it’s dry.

Lastly, you might find some kegs with double o-rings on their posts. While this may appear out of the ordinary, rest assured they function as effectively as those with single o-rings.

Diameter: 8-7/8″ (225mm)

Height: 22-1/4″ (565mm)

Weight: 9 lbs 9oz (4.34kg)

Volume: 4.75 gallons (18 liters) but some are also slightly more in full volume

Post Thread Size: 9/16-18 UNF Thread on both the IN and Out.

The fact is… the era of cheap and readily available used homebrew kegs is… done. I could give you a bunch of reasoning behind that opinion including one of the best sources for used kegs… de-listing used kegs, but I’ve got a regularly updated article on the topic you can check out.

Keg Connection Says…

“People have been receiving these new PREMIUM REMANUFACTURED KEGS and already love them! That’s because there hasn’t been a used keg on the market in this good of condition, EVER. They’re ‘used’ in a literal sense but each of these kegs has undergone an extensive refurbishing process. They have been meticulously cleaned, machine-polished, and fitted with new o-rings including the lid, pressure relief valve, and both liquid and gas dip tubes. Plus, we’ve added two new o-rings on each post.”

Ball Lock Vs Pin Lock Kegs!

Rebuild Your Kegs

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

Price, promotions and availability can change quickly. Check the product page for current price, description and availability. tag:lnksfxd tag:postsizes tag:tpr

Lid on Foam

Lid on Foam

Credit for this photo and build to UnworkableProphet

Credit for this photo and build to UnworkableProphet

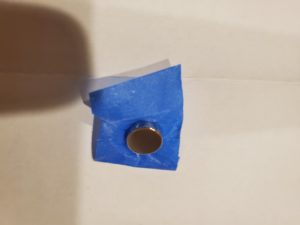

Alkaline Cleaner Distinct Blue Color

Alkaline Cleaner Distinct Blue Color

Thanks to

Thanks to

Bottom of Mash Basket

Bottom of Mash Basket