Why Won’t My Homebrew Keg Carbonate? Fixing Draft Beer Carbonation Problems

It’s a tale as old as time, or maybe not quite as old as time, but still old… your beer has finished fermenting, you excitedly transfer it to a keg and wait patiently. Well, maybe not so patiently. Every day or two you draw some beer to see where it’s at… it tastes amazing but it’s not carbonating. You think you’re just being impatient, but then the days continue to pile up. You’re getting a little carbonation, but not much. Is this beer broken? Or, have the basic principles of fluid dynamics just failed?

First Things First…

You’ve probably already done this, but you need to make sure your system is balanced and that both the temperature and pressure levels are set to correctly

See: Step by Step: Balancing Your Kegerator Draft System

Check For Leaks

You’ve probably already done this too, but you need to make sure your kegerator is leak-free.

- Step by Step: Finding and Fixing Keg CO2 Leaks

- Checking for Draft System CO2 Leaks – Using The Pressure Gauge Method

Why Your Beer Still Won’t Carbonate…

In my experience, continued carbonation problems are a reliable sign of… a CO2 leak. You may be convinced that your CO2 lines are leak-free, but… it’s possible you’re missing something. Even a very small leak will foil the carbonation process.

Gas is going to want to take the path of least resistance. Leaking out of a bad o-ring, or other slow, small leak is easier than dissolving into solution.

If you’re reading this odds good you’ve checked for fast, large leaks. If that’s the case, take a close look at the gas post o-rings and gas dip tube o-rings.

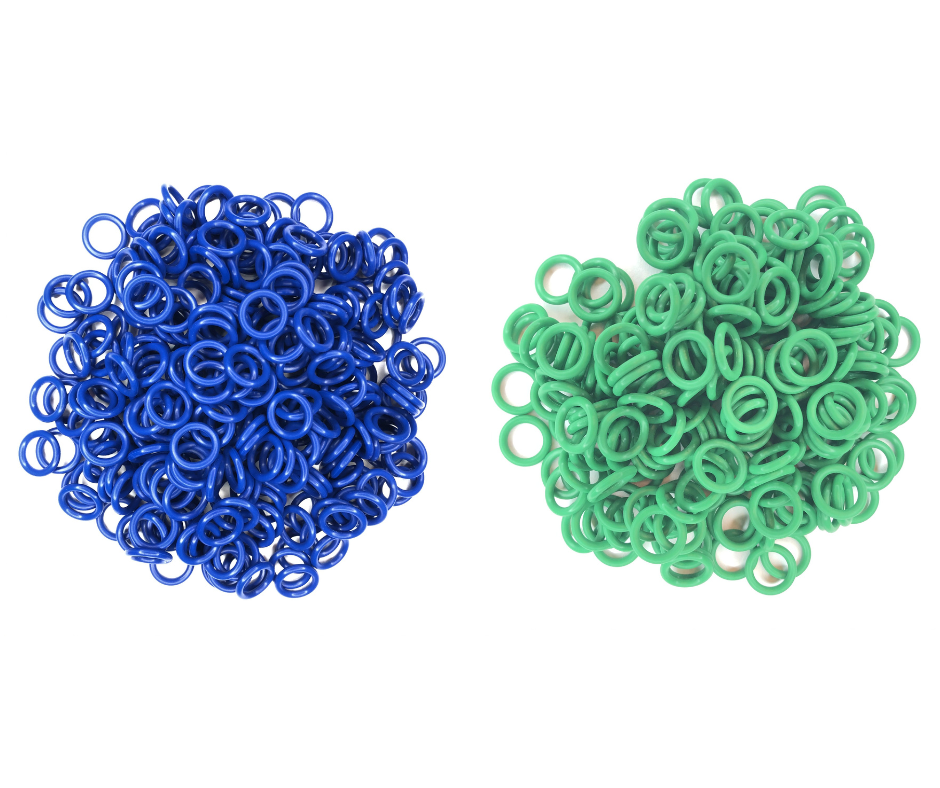

Color coded post o-rings. From our Keg Rebuild Post – Jump To: Replace O-Rings

Color coded post o-rings. From our Keg Rebuild Post – Jump To: Replace O-Rings

In my opinion the most difficult spot to check and the cause of many a lost CO2 tanks are… gas post o-rings.

Testing at this point using the “spray bottle method” (spray Star San everywhere and check for bubbles) is impossible or at the very least difficult and messy. Leaks will only surface here when a gas QD is actually engaged. The problem is, you can’t easily see that spot when a QD is on.

The problem stated more simply… You need a QD on to see if it’s leaking, but you can’t see it if a QD is on. You can use what I call the pressure gauge method to check for overall leaks. But even using that method you know that you have a leak but it gives no indication where it’s at.

Be quick to replace gas side o-rings… I’m quick to replace gas post (and gas dip tube) o-rings. Beyond slow and no-carbing beers, a bad gas side o-ring can lead to empty tanks. That’s a waste of time and money and it’s frustrating.

These o-rings cost pennies each when you buy them in bulk. Liberally replacing these can save time, money and frustration.

- Keg Post O-Rings

- Keg Dip Tube O-Rings

- Full Lineup of Bulk Food Grade O-Rings

- Bulk Keg Orings and Keg Repair Part Numbers

Valuebrew carries color coded post o-rings… “Green for Gas” and “Blue for Beer” they also carry pin lock post o-rings in bulk, Search “Post” at Valuebrew to see full lineup.

Valuebrew carries color coded post o-rings… “Green for Gas” and “Blue for Beer” they also carry pin lock post o-rings in bulk, Search “Post” at Valuebrew to see full lineup.

Related:

- How Often Should You Replace Keg O-Rings? – A Proposed Schedule for Keeping Kegs in Great Shape

- The Most Difficult Spot to Check for CO2 Leaks

- Rebuilding & Reconditioning Homebrew Kegs!

Color Coded Post O-Rings for Easy Identification:

Valuebrew carries two color schemes to color keg posts. Doing this allows you to quickly identify keg posts. Gray and Black match standard keg QD colors. Blue and Green are meant to be remembered by “Blue for Beer” and “Green for Gas”. All options are made from FDA rated silicone. Since they work equally well on gas and liquid posts you can also mix and match to come up with your own color coding standard.

Another Layer of Protection Against Leaks – Using a CO2 Monitor to Check for Kegerator CO2 Leaks

Pictured: INKBIRDPLUS Indoor CO2 Detector

Placing a CO2 Monitor with alarm inside of your kegerator can serve as another line of defense to protect against co2 leaks and loss. CO2 should not be building up in your kegerator. A CO2 monitor with alarm can alert you of this condition.

This is not a replacement for the steps outlined here, rather a another layer that could save you a trip to swap out a CO2 tank.

- Search Amazon for CO2 monitor with alarm

- Pictured: INKBIRDPLUS Indoor CO2 Detector, Air Quality Monitor, Tester for Carbon Dioxide, Temperature and Relative Humidity, Indoor CO2 Monitor with Alarm, for Grow Tents, Wine Cellars, Homes, Cars(PTH-9C)

More About Leaks: Step by Step: Finding and Fixing Keg CO2 Leaks

Also: Kegerator Tips & Gear | Keg Repair Part #s | Recent Keg Finds

Our Top Draft Resources This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds! This is a Top Post! See: All Top Posts Make sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions. tag:lnksfxd toppost:carbproblems tag:tpr

More Homebrew Finds!

I’ll also put in a vote for a CO2 air monitor. I’ve got the one that inkbird puts out and it was instrumental in identifying a CO2 leak in my kegerator setup and letting me know when I’d fixed it. CO2 should not build up inside the compartment of your kegerator when you have things right.

Elliott… this is a great idea!

One other big reason is Higher final gravity beers or beers with lactose added. These generally require a little more convincing such as shaking the keg rather than the burst carbonation technique