Hands on Review: Mark II Homebrew Pump w/Stainless Head

This review is by Homebrew Finds Contributor Brad Probert. Brad is an engineer, expert homebrewer and experienced reviewer. Grab a link to Brad’s website at the end of this review.

This review is by Homebrew Finds Contributor Brad Probert. Brad is an engineer, expert homebrewer and experienced reviewer. Grab a link to Brad’s website at the end of this review.

Mark II Pump with Steel Head

Let’s face it, pumps aren’t the most exciting piece of homebrew equipment you own. With the exception of the RipTide pump, they don’t have “features” you can impress your friends with. There are a few basic requirements, and once you get those met, you’re just looking for the lowest price. For me, the basic requirements are: 1) Magnetic drive, 2) Ideally a stainless steel head, 3) Temperature & splash protection, and lastly 4) Maximum head.

The MkII’s Magnetic Impeller

The MkII’s Magnetic Impeller

Several vendors offer what’s called a “Mark II Pump”. So you need to dig deeper than just the name when comparing pump offerings from different shops. One requirement, which is pretty much standard across beer brewing pumps, is what’s called a magnetic drive. Magnetic drive means you don’t have to worry about grease from shaft bearings getting into your wort. The other advantage is that you can close a valve- partially or completely- on the output side of your pump to reduce flow, and it causes no stress to your pump. Magnetic drive is pretty much standard in beer brewing pumps, but I bring it up because shopping on Amazon or eBay you might get drawn into something that isn’t.

Check Current Price & Availability:

MARK II BEER PUMP via Proflow Dynamics

Limited Time Deal!

PFD is taking 30% off their homebrew category when you use promo code BF30%. Considering their already, generally, great everyday prices, this is an outstanding deal!

ProFlow’s Homebrew Lineup – remember coupon code BF30% to get an additional 20% off

- This works with the MK II Pump!

- Shipping is an additional cost based on your location. Because of minimum shipping costs, it may make sense to place a larger order. Additional items may ship for minimal cost.

MK II Brewing Pump – remember coupon code BF30%

About Pump Features and Specs – What does Pump Head Mean?

Pump heads come in either stainless steel or some kind of plastic/resin. Some resins have a better temperature durability, so after many hours of operation they are less likely to break down and lose pressure/flow capability. Stainless steel doesn’t have this issue, but it also has more durable threads. Most wort pumps come with 1/2″ Male NPT at inlet and outlet so you can screw on hose attachments or ball valves. I’ve had bad luck with stripping threads off a polysulphone pump head even with the most careful attention paid to not cross-threading it.

The next key differentiator between pumps is temperature capability. Some are designed to handle cooler liquids and are maybe only rated to something like 80F or 180F. This simply isn’t good enough for brewing, you want something that can handle boiling wort temperatures (212F or hotter).

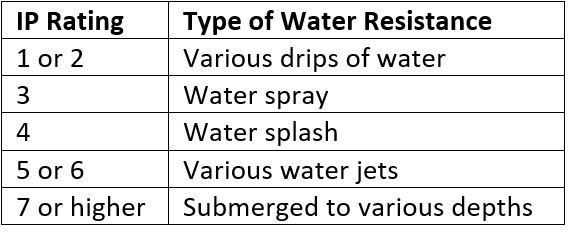

Another environmental spec you want to pay attention to is liquid protection. There are several big name homebrew pumps where the back end of the motor electronics is open to the air for cooling. This makes them vulnerable to leaky fittings or inevitable dribbles when disconnecting hoses. The international standard for water protection uses a rating system “IPxy”. IP Stands for Ingress Protection, then the first number (x) represents resistance to dirt/dust from getting in your pump, and the second number (y) represents its resistance to water getting in. The higher the number, the more protection. Here’s an abbreviated summary of the water protection ratings and what then mean.

IP Ratings Described

IP Ratings Described

The last pump spec to pay attention to is “head”. Head is a measurement of the height a pump can pump water. Stronger pumps can pump water to a higher level before running out of oompf. Think of pump head as your sort of bank account. There are various things you have to pay out of your “pump bank account”. To pump wort up to the height of your kettle you have to pay some. To push wort through your hose, you have to pay some. Your biggest expenditure is a counterflow chiller or plate chiller because of all of the small passageways. After paying everything out of your account, if you have some left over, you can flow faster. The higher the flow rate, the more the “tax” is for chillers and lengths of hose.

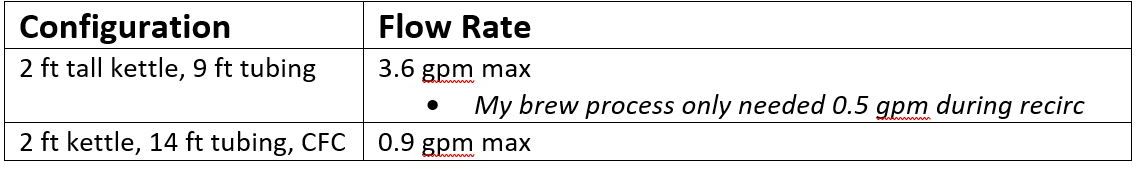

Unfortunately, knowing exactly how much head you need isn’t something you can calculate directly. Although there are reference tables for pressure drop in lengths of hose, and you can measure the height of your kettle, the bulk of your pressure drop comes when you use a chiller. And chiller manufacturers don’t publish the pressure drop numbers. In my Hands On Review section you can see some of the flow numbers from this pump in my system.

Hands on Review

Walking through the characteristics I listed above for the Mark II Pump sold through Pro Flow Dynamics, it checks the first box with having a magnetic drive. So I attached a ball valve to the output to control flow in recirculation. You never want restrictions to the inlet of the pump because this can cause the pump to starve, and can cause serious damage to beer pumps. This pump also has a stainless steel head, so I was able to wrap the threads 3 times with Teflon tape and screw the ball valve on with no issues. And no leaks.

MkII Stainless Pump Head Disassembled

MkII Stainless Pump Head Disassembled

The pump is rated to 248F, so it’s able to handle my post-boil wort circulation at 212F. The pump has an IP44 protection rating, which means it can handle splashes onto the pump body from any direction. So you don’t have to freak out if it gets wet during your brew day.

The pump has a max capacity of 19 L/min (5 gallons/minute), and a maximum head of 3.4 m (11.2 feet). During recirculation, with just hoses connected, I had way more flow capacity than I needed, so I had to close down the ball valve part way. When I added my Exchilerator Maxx counterflow chiller to the circuit, the flow significantly dropped. With the pressure drop of the chiller, I had to go full open on the ball valve on the pump to get a decent flow for cooling and then transferring to my fermentor. The lift for my kettle used 18% of the head, and the cooling lines used about 1-2%. The below table summarizes the numbers I measured.

Conclusions

The Mark II Homebrew Pump as part of a two vessel setup

The Mark II Homebrew Pump as part of a two vessel setup

So overall, this pump fully met the flow needs I had in this 2 vessel system, including when I had a counterflow chiller in use. It was quiet when running, met the necessary temperature requirements and was splash-proof. At the price point of this pump, I was surprised of how capable it was. If you have a similar brew set-up or flow needs, this pump is definitely worthy of consideration.

Check Current Price & Availability

MARK II BEER PUMP via Proflow Dynamics

More Photos

The Mark II High Temp Capable Wort Pump Mounted to a Piece of Wood

The Mark II High Temp Capable Wort Pump Mounted to a Piece of Wood

Editorial Note from HBF: There are a number of Mark II/Mk II offerings out there, sold by different manufacturers with slightly different branding. Some also quote slightly different features. The most notable one Brad found was water resistance. That to say, the unit reviewed in this post may be slightly different from other Mark/Mk II offerings.

More Pump Reviews!

More Homebrew Finds!

- Last 50 Finds!

- Top Deals – a curated list of the best deals

- Homebrew Reviews – one of the largest libraries of homebrew reviews in existence!

- Our Top Posts – tips, how-tos, resources posts and more

- Let’s be Friends!

Recent Deals!

10 Most Recent Homebrew Resource Posts & How-To’s!

By Brad Probert. Check out Brad’s website – beersnobby.com

Special Thanks to ProFlow Dynamics for providing the unit used for evaluation in this review.

This post may contain affiliate links. We may make a commission when you use our links. This will never cost you extra. Thank you for supporting Homebrew Finds!

Make sure the components you use are compatible and rated for your intended application. Contact manufacturer with questions about suitability or a specific application. Always read and follow manufacturer directions. tag:lnksfxd review:mkiipump rs:7 tag:tpr