Thank you to HBF Contributor Aaron Nord for this hands on review! Aaron is an advanced award winning brewer, a long time reader and a serial tipster!

Kegland Hop Bong

Keeping oxygen out of a fermenter after the initial yeast pitch is a goal of most fermentations, with a few exceptions being oxygenating a high gravity batch mid-way through fermentation, barrel-aged ales, or spontaneously fermented ales in open foeders. For a homebrewer who wants to brew a beer outside of those exceptions noted, avoiding oxygen introduction after fermentation has begun is paramount to a quality finished beer, a goal which is sometimes a difficult to attain. Notably, adding dry hops, other flavor components (e.g. wood chips or coffee beans), or clarifying agents (e.g. gelatin fining or Biofine) presents a challenge for most homebrewers if they want to avoid oxygen exposure in the fermenting wort.

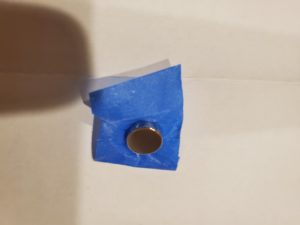

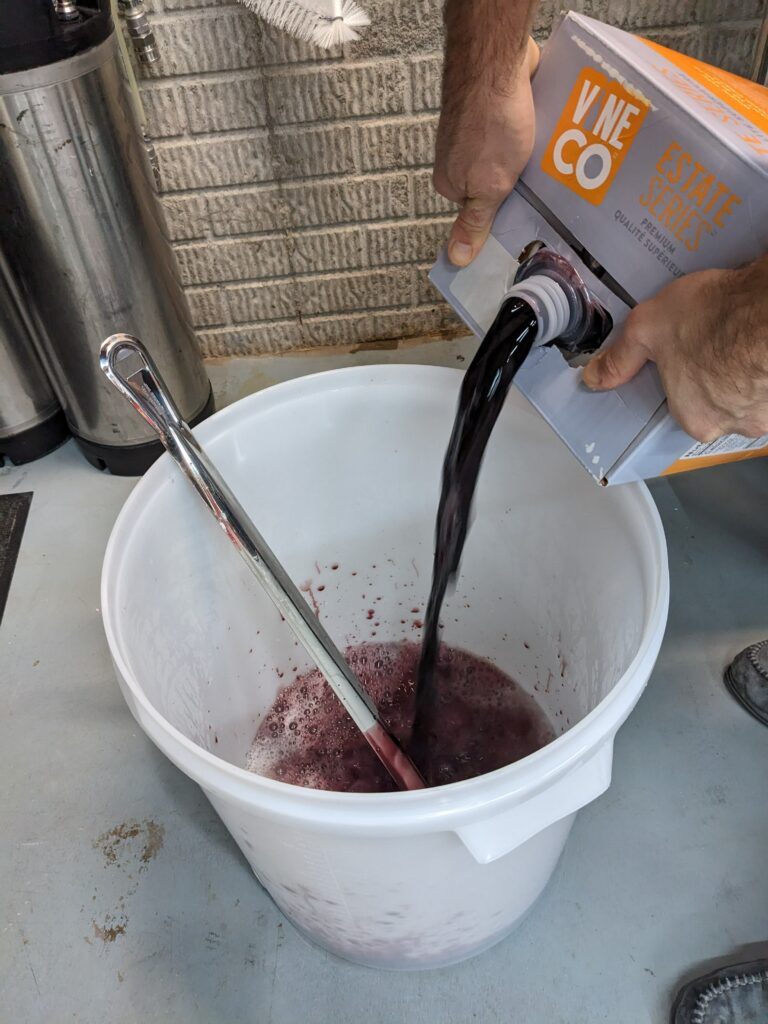

There are workarounds and ways for homebrewers to limit oxygen introduction, conceived upon by crafty brewers over the years. Dry hops for example, can be suspended in a muslin bag above the wort by placing a magnet inside the bag and its mating magnet on the outside of the fermenter. In this way, the hops will be in the fermenter at the beginning of fermentation and can be dropped according to the dry hop schedule by simply removing the outside magnet, all without opening the fermenter. Or, to add clarifying agents without cracking the fermenter lid, a brewer can utilize a plastic bottle with a carbonation cap. This method entails adding the liquid substance to a plastic soda bottle and pressurizing the bottle with CO2 via the carbonation cap, purging it, and repeating the process multiple times to ensure the gas inside the bottle is mostly composed of CO2. Then, by using a ball lock jumper, the pressurized bottle can be connected to a fermenter’s ball lock post, if equipped, and the liquid will enter the fermenter, so long as the pressure in the fermenter is less than that of the bottle.

Although these workarounds exist and cut the mustard for my purposes, I was excited when I found out that Kegland was set to release a product that appeared to be a simpler solution all around. In looking into it further I found that it was advertised to have additional uses, aside from the main feature of enabling hop, flavor, or fining additions to the fermenter while limiting oxygen ingress. This highly anticipated product is called the Hop Bong.

I have been a proud owner of a Kegland FermZilla All Rounder fermenter – Hands on Review – for over two years now and have nothing but good things to say about it. As a manufacturer, Kegland is a homebrewing gear innovator and a leader in the market. They are continuing to come up with novel equipment and tools that span their wide array of product offerings including many for their FermZilla fermenter line. I was excited to see what the Hop Bong could offer as an addition to my All Rounder fermenter.

Kegland Hop Bong Current Price & Availability:

via MoreBeer

via William’s Brewing

Continue reading →

Lid on Foam

Lid on Foam

Alkaline Cleaner Distinct Blue Color

Alkaline Cleaner Distinct Blue Color

Bottom of Mash Basket

Bottom of Mash Basket

Controller and Probe

Controller and Probe

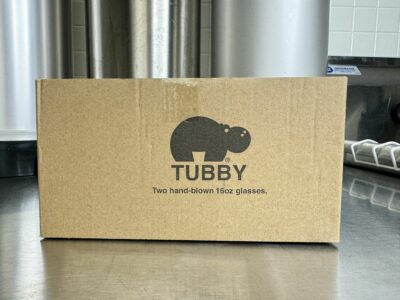

A look at the box

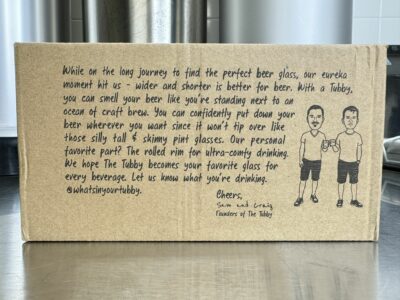

A look at the box The other side of the box. This is one of the better looking keg boxes I’ve run across.

The other side of the box. This is one of the better looking keg boxes I’ve run across.